How to Clean and Lubricate Bearings

To keep your bearings at peak performance, it is an excellent idea to regularly clean and lubricate them. This will extend the lifespan and durability of your bearings while ensuring they deliver maximum speed.

Note: Avoid contact with water & sand at all costs.

The lifespan of a bearing is significantly reduced when subjected to a damp and filthy environment during use or storage.

Steps for Cleaning and Lubricating Bearings on Skates, Skateboards, and Scooters

Step 1

You will need: A cleansing solution such as a grease-dissolving fluid like Fluid wash, a watertight container, a drawing pin or craft knife, a small brush, and new oil/grease.

Remove bearings from the wheel. Watch the YouTube video at the top to learn how to take the bearings out of a wheel. The demonstration occurs on a skate, but the method is identical for skateboards and scooters.

Detach the wheels and remove the bearings.

Step 2

Utilise the brush to clean all outer surfaces of the bearings until they are entirely free of grime.

There are two types of bearings to maintain: open and closed. Open bearings are straightforward to maintain, while closed bearings require careful shield removal.

Clean the outside of the bearings.

Step 3

If your bearings have seals, they can be taken off with a drawing pin.

Certain closed bearings with metal shields have a small C-clip holding them secure. This needs to be removed with the drawing pin before taking the shield off.

Don't forget to clean the seals and C-clips if present.

Seals, without a C-clip, are removed from the bearing using a drawing pin or a craft knife.

Step 4

Place the bearings into a sealed container filled with the cleaning solution, then briskly shake the container for several minutes. This action will help to break down any accumulated grime.

Begin with brushing the bearings clean and then follow up with a cleansing agent.

Step 5

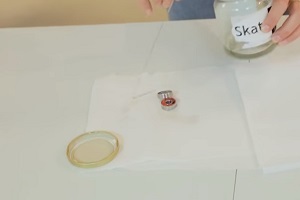

Take the bearings out of the container and remove any remaining cleansing agent by spinning the bearings. Alternatively, use an air compressor to blow out the fluid. Set the cleaned bearings on a clean cloth or kitchen paper.

Bearings have just been taken out from the container with the cleaning agent solution.

Step 6

Ensure the cleaning process was effective. Hold the inner ring of the bearing and give it a gentle spin. If it doesn’t rotate smoothly or you hear a grinding noise, the cleaning wasn’t thorough enough. In such cases, the cleaning process should be repeated with a fresh amount of cleaning agent. Severely dirty bearings may require 2-3 repetitions.

Check the thoroughness of the cleaning by spinning the bearing.

Step 7

Place the bearings back on the clean cloth or kitchen paper. They are now ready for lubrication. Apply 1-2 drops of oil (no more, as excess can attract dirt) or spread 3 mm of grease evenly in the bearing.

Ensure the oil/grease is well spread by spinning the bearings (this can be efficiently done by attaching the bearing to a drill).

1-2 drops of oil are meticulously applied to the bearing.

Step 8

Lastly, reinstall the shields on the bearings and fit the bearings back into the wheels of your skates, skateboard, or stunt scooter.

Seals are affixed to the cleaned and lubricated bearings, which are then reinstalled onto the wheels.

Post-Cleaning and Lubrication Steps

Once the bearings are cleaned and lubricated, you may need to travel a few miles before the oil/grease is fully distributed in the bearings, allowing them to operate at their best.